Impact Recording Device (IRD)

TM

We understand the needs of the agricultural community because we are a part of it! That's why the IRD is still the Global Standard.

The IMPACT RECORDING DEVICE (IRD) is an advanced technology tool for monitoring potentially damaging impacts to your fruits, vegetables and food products. From the field to the processed package and all points in between, the IRD will identify sources of damage allowing you to make adjustments to handling systems and protect quality.

<

>

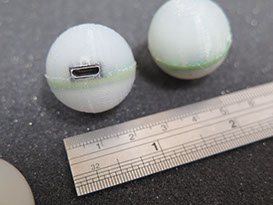

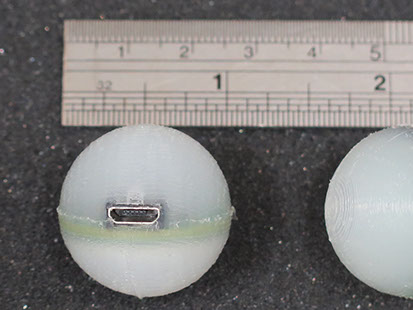

Series 500 IRD

The Series 500 Impact Recording Device has all the same great functionality of the Series 400 but has been updated for improved user experience and ongoing improvement. We've changed the connecting port to a Micro USB for easier communications and charging of the unit. Improved battery life and other features are all part of our commitment to reinvest in the technology and remain a leader in bruise evaluation in agriculture.

Force and Duration of Impact are the true measures of damage potential

Many devices on the market measure only the G force and ignore the equally important component of time duration. Not all impacts are created equal. Surface characteristics, G force and duration all contribute to understanding what impacts are of importance and which are less so to your product quality.

Impact Recording Device

-Reduce bruise and shatter damage to fruits, vegetables and other food products.

-Maximize incentives, bonuses and other merit compensation.

-Improve produce appearance and customer/buyer acceptance.

-Reduce post harvest respiration and disease loss.

-Improve storage and shelf life of fruits and vegetables.

-Accurately and reliably calibrate handling equipment performance across locations, suppliers or seasons.

-Calibrate handling equipment prior to harvest or packaging to avoid unnecessary bruising.

To subscribe to our IRD mailing list please click here. We periodically send product updates and other relevant information regarding the IRD.

Identify bruising impacts

Improve handling systems

Protect quality and improve profit

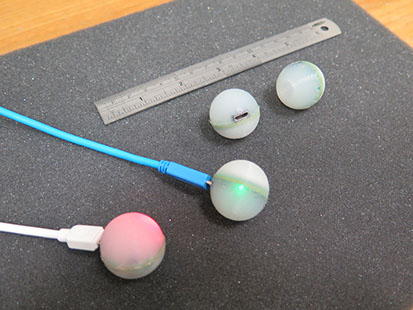

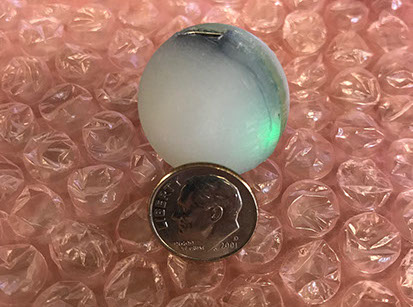

1 Inch IRD available for small Fruit and Veg

In a big leap forward ,we've redesigned the IRD using new technologies and can now offer a 1 inch device for testing smaller fruits and vegetables. Our 1 inch IRD is a perfect fit for soft fruit such as blueberries, cranberries, cherry and more. Our 1 inch IRD has LED functions for user identification of the device state as well as aiding in the tracking of your device through handling systems.

This device creates the opportunity for a number of industries to start using an Impact Recorder to identify areas of their handling systems that can be improved. The IRD can be used to identify impacts during handling that are damaging your products or affecting the efficiency of your operations. Techmark works with many producers worldwide to evaluate handling systems and identify opportunities to improve. For a quote or questions please email techmark@techmark-inc.com

Consulting and Special Projects

Techmark offers consulting services on a project basis. We can quote a specific project or training session after talking with you about your goals and the scope of the work. We have worked on handling system worldwide and can help you identify best practices as well as train staff in using the IRD. To discuss an on-site consulting project please contact us at techmark@techmark-inc.com

Testing for a Potato Farm in North America

13 - 13

<

>

How much is bruise and physical damage costing your organization each season?

Using internationally patented technology the IRD identifies the location and severity of impacts delivered to produce during handling procedures. The IRD is transferred through machinery and other handling systems with the normal course of fruit and produce, this allows the IRD to experience the same "bumps and bruises" that your commodity is experiencing. Impact data is recorded and stored on board the IRD, later this data is uploaded to your tablet or PC for analysis. PCIRD, our IRD software package, will generate reports from the data collected and allow for straight forward interpretation of where the most significant impacts occur.

The Science

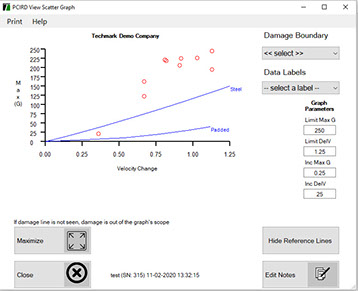

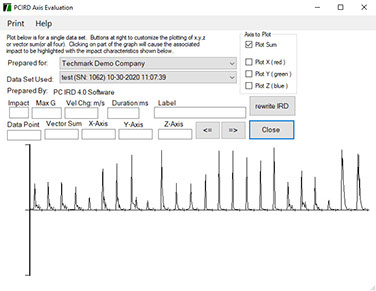

Severity of impacts is calculated in both maximum acceleration (G) and velocity (m/s) for each impact. This is the key to understanding where the damaging impacts occur; not all impacts create damage, to separate the non-damaging impacts from the damaging impacts you must know BOTH the acceleration and the velocity - Techmark's IRD is the only product on the market that measures both of these critical data points.

To better understand this process, imagine an apple being dropped from 12 inches onto a rubber surface. Now imagine the same apple being dropped onto concrete. It is possible in this scenario that the impact G force is the same for both drops BUT the damage caused is significantly different because of surface characteristics. The rubber surface will be able to absorb the G force over a greater amount of time thereby changing the velocity and causing less damage to the apple. The concrete will have a short time period of velocity change and the energy of the G forces will cause damage to the apple in the form of bruise as the energy is absorbed by the fruit. What does this mean for you? It means that the IRD can identify where bruising potential exists and allow you to make a change. Sometimes the change is as simple as reducing a drop or adding a padding material to a corner. Other damage points may be less identifiable and need more significant alterations to avoid product damage.

The spherical shape of the IRD creates a consistent evaluation of the handling system. All points on a sphere are equidistant from the center. This shape provides a consistent interaction with the systems it travels through. No fruit or vegetable is of exactly the same dimensions, neither are the handling systems they move through making it important to use a measuring device of a consistent shape and weight to provide reliable data that can be compared to other data generated in the same manner.

Techmark's I.R.D has been a global standard for bruise evaluation of fruit, vegetable and food product handling systems for over 25 years. Tested and supported by researchers and growers worldwide, the IRD is responsible for reducing waste and adding to the bottom line of countless operations.

Techmark's IRD is a global standard for evaluating fruit and vegetable handling systems.

How much is damage from handling costing your operation annually?

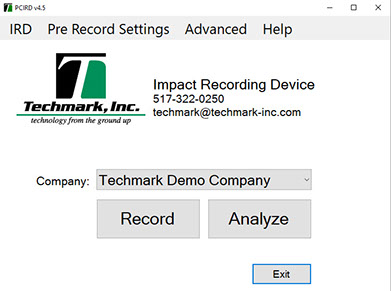

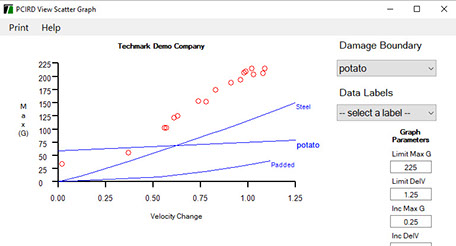

PCIRD 4.5 is the program used for operating the IRD and analyzing data. Data can be viewed in multiple visual formats as well as be downloaded for a higher level analysis. Industry supplied thresholds are provided for some crops while customizable thresholds for other crops can be developed. The impact G Force and Duration data can be viewed per impact.

Each impact is very unique. The mass of the fruit or vegetable, the surface characteristics, duration and G force of the impact all create a snapshot of what's happening to your product. The IRD will allow you to understand where the highest damage potential exists and allow your teams to make changes that reduce the number of damage causing impacts.

The bottom line is that this tool can be used to reduce product less caused by handling system impacts.

Scatter graphs allow for quick looks at what impacts may be above damage thresholds

The IRD is a tool to quantify and educate your teams on where product damage is occurring.

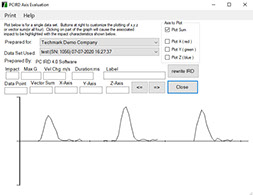

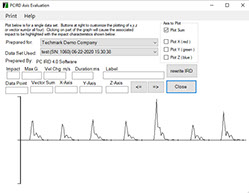

An axis evaluation lets you see how different a padded surface impact is from a hard surface such as a metal conveyor wall

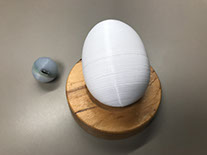

Techmark's EGG IRD offers the user an option to create different sized egg shells while using the same Impact Recording Device. This flexibility is one of the great reasons to contact Techmark about your operations needs.

Egg Handling Systems

Techmark Inc. Technology from the ground up 1-517-322-0250 www.techmark-inc.com techmark@techmark-inc.com

Techmark, Inc.

15400 S. US 27

Lansing MI 48906

All materials copyrighted.

2019